The role calibrated imagery plays in your fertility ROI Using dirty data when trying to…

Check, Check … Zero Check?

Using Zero Check Strips for In-Season Data as an Alternative to N-Rich Strips

By now, many may have heard about using N-Rich Strips as a reference or check strip in a field. However, you may be scratching your head on how to get your growers onboard with this methodology. Zero Check Strips is an option you may want to offer to those struggling with the concept.

WHAT IS A ZERO CHECK STRIP

For the N-Rich Strip option, we have a high application rate in one part of the field, and we want the rest of the field to catch up. In these cases, the rest of the field receives a minimal nitrogen application rate. The N-Rich Strip shows up when the field uses up its residual nitrogen, which means the field says it’s time to apply more nitrogen.

So, we think of the field as the N-Rich Strip and the Zero Check as the farmer practice or environmental potential.

Read more about N-Rich Strips in our blog post.

HOW IT IS APPLIED

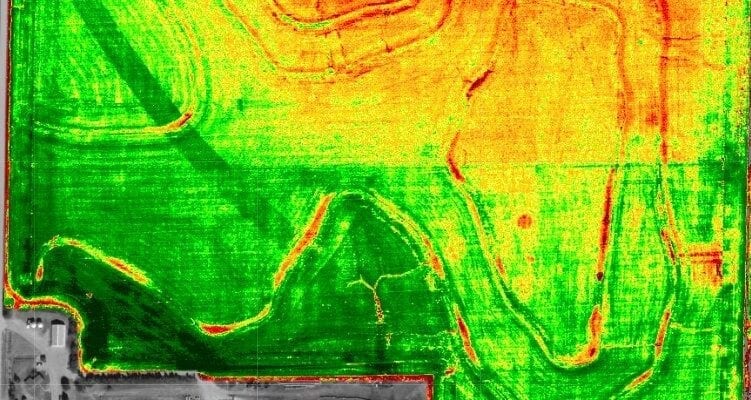

In a Zero Check scenario, we just turn the applicator off or pre-load a script into the applicator in one part of the field and apply a minimal nitrogen application rate to the rest of the field. If you’re applying manure, it’s the same concept just skip an area. We can then calculate if you need to apply more nitrogen when the Zero Check starts to show up. When this happens, the strip has run out of residual nitrogen, while the rest of the field has plenty.

THE DIFFERENCE BETWEEN AN N CHECK AND ZERO CHECK

For the Zero Check approach, the same framework is used but assumptions are switched. In a Zero Check situation, it’s assumed a significant amount of pre-plant nitrogen has been applied.

The pre-plant nitrogen application amount is the only information needed to run a Zero Check field recommendation. Once the strip is visible, we look at the potential yield of the Zero Check and the rest of the field.

If the Zero Check could yield 40 bushels and the rest of the field can yield 80 bushels, we know the entire field before the Zero Check was applied needs 80 pounds to catch-up. However, if 60 pounds of nitrogen was applied at pre-plant, then only 20 pounds nitrogen needs to be applied. If 100 pounds was applied at pre-plant, then no additional nitrogen is needed.

HOW TO KNOW WHICH ONE TO USE

Knowing whether to use an N-Rich Strip or a Zero Check Strip is dependent upon the grower. If your growers are struggling with the concept of applying extra nitrogen for an N-Rich Strip, then a Zero Check Strip could be an option. The only difference is the methodology. There’s no difference in regard to the recommendation quality or algorithm.

Zero Checks are a great option in corn because it can be a challenging to get growers to cut back on pre-plant applications.

THE NINJA WAY

Using past data is not an accurate representation of the current nitrogen need. Reference strips deliver current information on the amount of nitrogen the environment provides (mineralized from soil organic matter and/or deposited in the rainfall). Strips say a lot about the environment. In years of high production, reference strips will likely indicate the need for more nitrogen and indicate the need for less in years where growing conditions are poor.

Without this simplistic ‘yes’ or ‘no’ methodology, you are dependent upon past, inconsistent data, and you’re left guessing when the right time is to apply. Letting the field do the talking helps eliminate guesswork. With a strip and our system, you know when and how much nitrogen to apply.

As we’ve mentioned before, it’s important to make the tools fit for your specific regional needs and practices and not the other way around. If you need help in figuring out how to implement N-Rich Strips or Zero Checks into your program, our agronomy ninja, Tyler Lynch, can help you with the best approach for your area. You can reach him via email at tlynch@ninjaag.com.

SOURCES